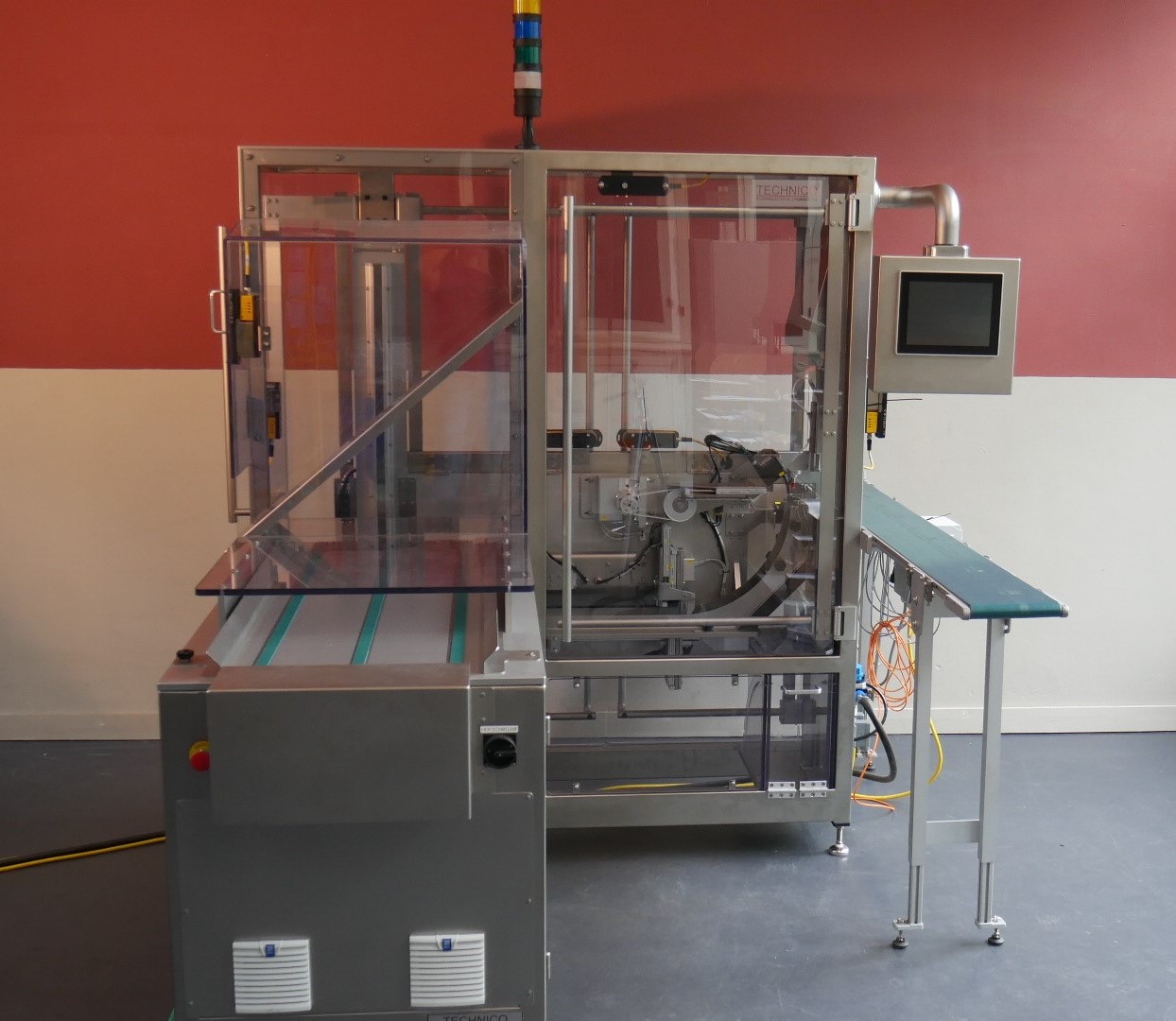

Tray Unloader

Component dispenser

Key Features

- Unloading trays

- Tagserts, booklets, blisters, etc.

- Presenting them one by one.

- Checks codes on both sides with an fail safe reject.

- Ergonomic, safe and easy operational by one operator.

- Small foodprint.

- Product thickness from 1 to 50 [mm].

- GMP compliant.

- Speed up to 100 products a minute.

- Short delivery time.

The tray unloader, also known as the component dispenser, is designed to empty trays containing tagserts, booklets, blisters, etc. The (pharma) code on both sides of the product is checked. An operator manually places full trays on the green belts. The component dispenser processes the trays and presents the products while verifying the (pharma) code on both the top and bottom sides. Products without a code, or with an incorrect (pharma) code, are rejected. The component dispenser then places the products on a conveyor or directly into a carton, which is encoder-linked to the stacker for perfect synchronization. Empty trays are automatically deposited into a kit bin.

This GMP-compliant machine has an ergonomic design, is easy to clean and can be operated by one operator.

Design Options

- Any size/product can be processed.

- Tagserts, booklets, blisters, etc.

- Speed can be doubled by using a double stacker.

- Brand of camera control system can be chosen freely.

- Experience with Cognex, Laetus, Baumer and many more.

Customized to your needs

The component dispenser from Technico Pharmaceutical Engineering can be customized to meet your specific requirements. The component dispenser can be used for booklets, blisters, tagserts, with different dimensions, safety circuits and other components. Technico can provide full documentation with the machine upon request.

Please feel free to contact us so we can discuss the possibilities for your specific needs.